HIGHLIGHTS

The specialists who carried out the PFS analysis reached the following conclusions:

- The capital, operating, and price projections are realistic;

- The total PFS can be viewed as "advanced research" with sufficient precision and confidence that potential investors can base their decisions on its findings.

Pre-Feasibility Study

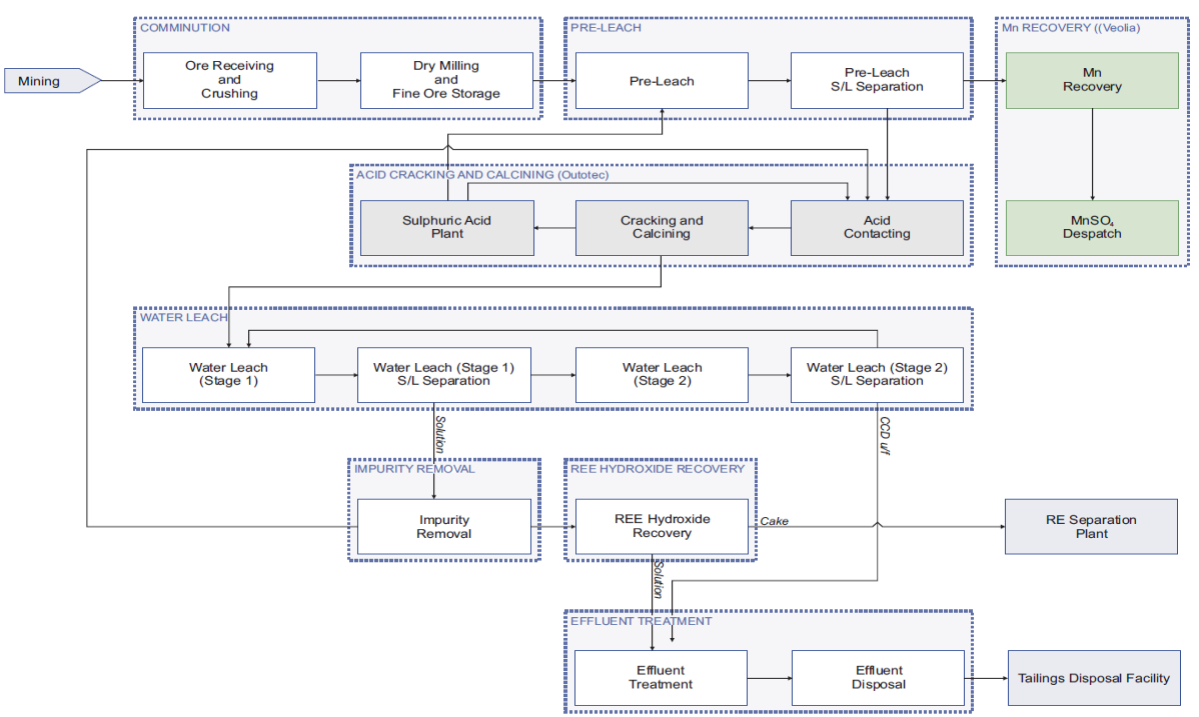

Process enhancements completely remove major operational issues associated with the conventional acid cracking process.

- Supplying dry, free-flowing feed rather than wet paste;

- Preventing corrosion by eliminating acid condensation;

- Allowing 80% recovery of sulphur;

- Allowing maximum stabilization of impurities, resulting in lower impurity removal costs;

- Reducing residence time from approximately one hour to approximately ten minutes;

- Operational stability and significantly improved process control;

- Lower operating cost.

In addition to the benefits obtained from the manganese pre-leach, process improvements significantly reduce the need for beneficiation prior to cracking.

Projected Metallurgical Flowsheet

Using Acid Cracking Process for High-Quality Material Production

The use of fluidized bed reactors rather than kilns will result in:

- Improved temperature and residence time control for more effective cracking;

- No corrosion as the temperature is kept above the acid dew point;

- No material buildup or obstruction;

- Efficient heat transfer;

- Approx. 80% lower residence time;

- Approx. 50% heat recovery;

- Approx. 80% sulphur recovery.

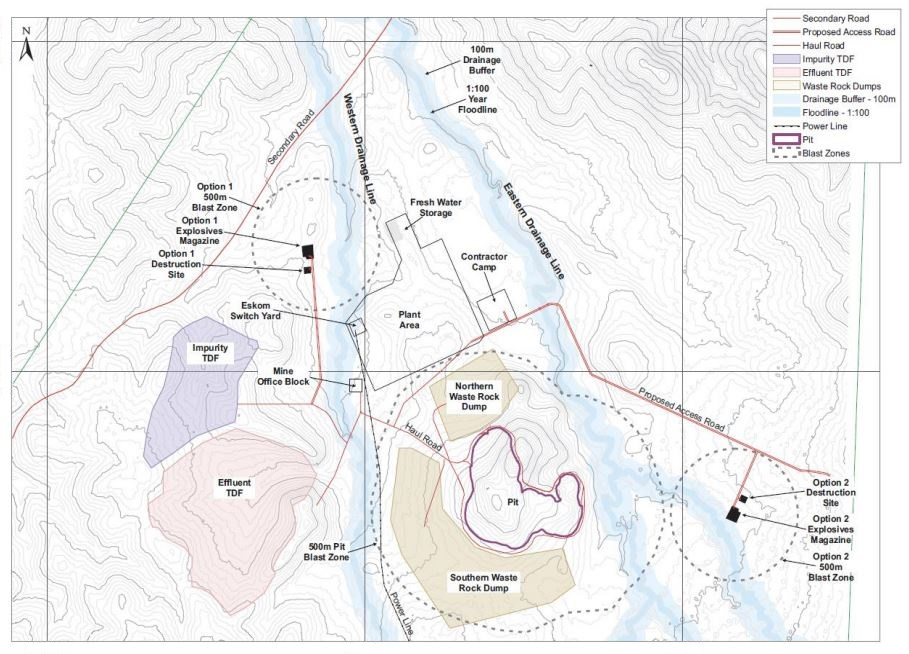

The Lushan Mine Layout

Outcome

At the Lushan Project, a technically feasible and economically sound open pit mining and beneficiation operation with a production capacity of 6,900tpa TREO for four years and then up to 13,600tpa TREO for a total mine life of 35.5 years can be carried out, as well as the production and sale of a feed grade manganese sulphate by-product.

Environmental authorization and mine permitting are well established, and no substantial environmental or legal regulatory concerns or risks that cannot be managed or reduced have been discovered. The requisite power and water infrastructure for both the Lushan Mine and the Separation Plant can be sufficiently provided.

Environment

Our environmental management strategy is based on a thorough identification, evaluation, and management of risks at all stages of the project, including exploration, development, operation, and closure. A Risk Framework is used at the mine site to identify and manage environmental concerns.

Our Environmental Policy directs our approach as we acknowledge that environmental performance is an important component of our business:

- Make employees, contracts, and vendors aware of their environmental responsibilities;

- Plan for mine closure diligently and proactively;

- Manage all waste streams responsibly, reducing or recycling waste on a regular basis;

- Ensure that resources and management systems enable legislative responsibilities and internal standards;

- Report on environmental performance on a regular basis and take corrective action when results fall short of expectations;

- Actively develop an environment-friendly culture that honors cultural and community values;

- Establish, review, document, and monitor environmental objectives and targets to continually improve environmental performance;

- Comply with all applicable environmental regulations and statutory standards, and apply appropriate internal standards where necessary;

- Control and manage environmental risks associated with activities by putting in place procedures to identify, analyze, control, and monitor them;

- Educate and train employees and contractors to assist with the project’s environmental management.

Health and Safety

We are dedicated to making sure that the health and safety of our employees and contractors are a priority in our decision-making. We strive for the highest degree of performance by implementing risk-based systems and management methods that are appropriate for work. Our goal is to maintain a safe and healthy workplace.

Establishing responsibility and accountability among employees and contractors encourages safe work procedures and practices. Our health and safety management systems and practices establish clear guidelines for visible leadership, as well as our commitment to continual training and staff development.

We promote proactive, positive safety awareness throughout the organization and foster a culture of continuous improvement. We consider the safe completion of our Project to be of paramount importance, and we have established a set of standards that apply to all employees and contractors who operate for or on behalf of our organization. These standards establish minimum expectations and promote consistency throughout our business, while also giving contractors the freedom to work under their own health and safety procedures.